- No products in the cart.

Menu

Start typing to see products you are looking for.

In observance of Sabbath

our checkout is closed and will be available in Feel free to browse our site and add items to your cart or wishlist. Notify Me When Open

Browse Categories

TPI Workstation 24" Fan 120 Volt 360 Degree, Vertical Swirl Air Circulator Venting Exhaust Fans U24-TE

$ 147.99

Availability:

Out Of Stock

Lowest Guaranteed Price!

At Wholesale Home Improvements, we do our best to offer amazing prices and incredible deals on all of our items.

Need a price match? Simply call us at 201-351-1900, chat with us or email us at info@wholesalehome.com.

Since we are authorized dealers we can beat any offered price on any brand we carry. We are so confident that no one can beat our prices, that we offer a lowest price guarantee on bulk and volume orders. If you need a quote for any item of the listed brands below please contact our wholesale dept via email sales@wholesalehome.com or by phone 201-351-1900 ext 3

When you shop with us, you don't just get what you paid for, you get much more!

Our 30-Day Hassle Free Return Policy

If you are not 100% satisfied with your purchase, you can return it to us for a full refund.

In order to process your return, you can do it yourself with our easy and fast Return portal or you can feel free to contact our customer service at info@wholesalehome.com.

Note:

- You can return your purchase for up to 30 days from date of purchase.

- Products must be in the same condition in which they were recieved, in the original box and/or packaging and with all of the original accessories.

- Customer is responsible for returns shipping cost if return is not due to our error

Free Shipping

We offer free shipping on all our orders witin the Continental USA - No Minimum Required.

We also offer multiple expedited shipping options such as 3 day, 2 day, and 1 day shipping. All orders (of in-stock items) that are placed Monday through Thursday before 2 PM EST will ship the same day. Orders placed on Friday before 11 PM EST will also ship the same day.

Description

The TPI Corporation U 24-TE single-phase 24-inch diameter industrial workstation fan has a built-in swivel mount and is suitable for providing air circulation at an industrial workstation. The blade assembly, consisting of a steel hub and spider, holds the fan head’s three aluminum paddles, which are enclosed by front and rear powder-coated steel wire guards for strength and resistance to corrosion.

The built-in mount swivels 360 degrees vertically and horizontally for precise direction of airflow. The motor of the TPI workstation fan is totally enclosed, making it suitable for use in conditions that standard, unenclosed motors are not, such as in the presence of dust or other airborne debris.

This TPI fan compact fans mounts quickly with one lag screw or bolt to workbenches, walls, beams, steel shelving, machines, ceilings or any surface. TPI Wall-Mount Workstation Fans feature a 3-speed industrial fan head that rotates 360 degrees to deliver air in any direction. Totally enclosed, sleeve bearing, permanently lubricated motor.

Also includes: pull chain switch, 10'L, 3-conductor cord, and three aluminum blades. Meets OSHA standards and is UL-listed. Mounting brackets to wall, ceiling, or pole are not included and must be purchased separately.

Specifications:

- Permanently lubricated, totally closed sleeve bearing motor

- Switch type Pull chain

- Cord 10-foot SJT type three-conductor cord

- Blades Aluminum x3

- Blade guards Powder-coated steel wire

- Cubic feet per minute (CFM) 5850 / 5200 / 3600

- Weight 23 lbs.

- Dimensions 27 x 26 x 10.5 inches (H x W x D)*

- 3-speed, 2.4 amp, 120 volts, single-phase, 1/8 horsepower, permanently lubricated, totally closed sleeve bearing motor1/12 horsepower,

- Tilts for convenience

- 2.4-amp, 120-volt, single-phase, 1/8 horsepower,

- Pull chain switch

- Head rotates 360° vertically and horizontally

- Coated steel guards

- Steel hub with spider aluminum paddle blades

- Meets OSHA standards

- Intertek listed

Industrial fans are used in workplace environments to exhaust fumes or direct airflow. Most industrial fans have coated metal parts and lubricated motors that are permanently sealed to help protect against environmental hazards, such as dirt and airborne debris or corrosive fumes.

They can have fan blade cages that meet workplace safety standards, as well as a variety of mounting mechanisms for precise placement to direct large volumes of airflow. Electronic circuitry for industrial fans matches the power specifications found in the workplace and provides the initial torque needed to start up a large blade fan. Industrial fans are used in warehouses, gyms, and other commercial environments to ventilate spaces and to circulate air.

*H is height, the vertical distance from lowest to highest point; W is width, the horizontal distance from left to right; D is depth, the horizontal distance from front to back.

Info and Guides

In The Box:

- 1 x 3-speed motor

- 1 x Pull chain

- 1 x 10-ft. SJT-Type 3-conductor cord

- 1 x Aluminum fan blade assembly

RELATED PRODUCTS

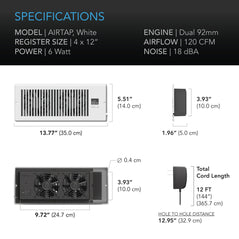

AC Infinity - AIRTAP T4 4x10" Register Fan with LCD Thermal Control

| Fits Register Sizes | 4 x 10 in. |

| Total Airflow | 120 CFM |

| Noise | 18 dBA |

O2COOL - 10-Inch Portable Smart Power Fan - AC Adapter & USB Charging Port

O2COOL's 10-inch portable fan is perfect for indoor and outdoor activities, use in a hot office or school, on a picnic and especially during a power outage. Fan is rechargeable...

AC Infinity - AIRTAP T4 4x12" Register Fan with LCD Thermal Control

| Fits Register Sizes | 4 x 12 in. |

| Total Airflow | 120 CFM |

| Noise | 18 dBA |

AC Infinity - AIRTAP T6 6x10" Register Fan with LCD Thermal Control

el active" id="product-warranty"> Product Identification Manufacturer AC Infinity Inc. Product Name AIRTAP T6 Product Model White: AC-RBF6-W | Bronze: AC-RBF6-B Product and Mounting...

Honeywell L4064B2236 Combination Fan and Limit Furnace Control

| Insert Length: |

8" |

| Temperature Range: |

100°F to 250°F |

Westinghouse - Modern Industrial Style - 56-Inch Ceiling Fan and Wall Control - White

| Mount Type | Down Rod Only |

| Number of Blades | 3 |

| Control Style | Wall Control |

AC Infinity - AIRTAP T6 6x12" Register Fan with LCD Thermal Control

| Fits Register Sizes | 6 x 12 in. |

| Total Airflow | 160 CFM |

| Noise | 20 dBA |